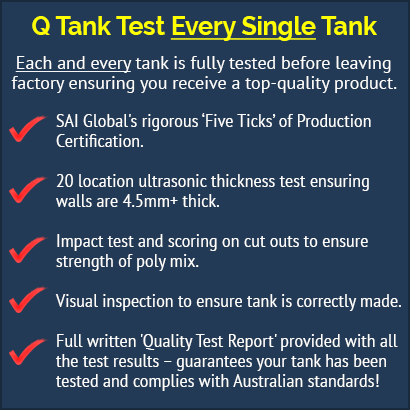

The Australian standard for poly water tanks (AS/NZS 4766) requires only 1 in every 10 tanks produced to pass a strict set of tests. This standard specifies requirements for the design and manufacture of polyethylene storage tanks. QTank’s commitment to quality exceeds the Australian standards as they test every tank and supply the results to the purchaser.

Quality Test Report

QTank lead the way with manufacturing high-quality poly tanks. QTank are the only tank manufacturer we know to test every tank they make and include a report of the results.

Each QTank must pass three tests before leaving the factory floor:

- Ultrasonic Thickness Testing – ultrasonic measuring equipment measures the thickness of your tank at 20 locations including the roof, wall and base.

- Impact Testing – tests on hole cutouts on your tank are performed that ensure the polymer chains have correctly bonded and aren’t brittle.

- Visual Inspection – experienced staff inspect your tank interior and exterior to ensure no abnormalities.

When finished a full written ‘Quality Test Report’ is provided containing all the test results on your tank.

Ultrasonic Thickness Testing

QTank use an ultrasonic measuring device to determine the thickness of tanks to within 0.1 mm accuracy. The device on 20 sections of the tank including areas of the lid, wall and base. Areas are also tested at a similar height on the tank, making sure they are a consistent width to ensure maximum structural integrity and long-term durability.

The Australian standard requires that no tank section thinner that 4.5mm. QTank use more poly in their tanks to ensure water tanks easily exceed this thickness, verifiable by the fact QTank tanks come with a guaranteed weight which is often higher than other tank brands at comparable sizes.

You will receive the complete results of the thickness test with your test report, so you will know the thickness in all tested areas of your tank.

Impact Testing

QTank measure the impact strength of your tank’s plastic mix to ensure the mix is high-quality, will last a long time without becoming brittle (which also leads to colour fading), and is strongly made.

- When the inlet strainer is cut from the tank, 2 samples of the tank are removed ready for impact testing. (one is supplied with the tank, the other is kept at QTank for warranty period of the tank).

- The sample is allowed to cool slowly at room temperature for 24 hours, then cooled to -40° Celsius for 6 hours to stress the polymer chains to their limits.

- A 9kg dart is dropped onto sample to test its strength (see adjacent image). If the sample cracks or is pierced then the tank fails the test and will not be sold.

Visual Inspection

The interior and exterior of the tank is visually by QTank’s experienced staff to check for defects. When rotary moulded polyethylene water tanks are over-cooked they degrade from the inside out. It takes the trained, experienced eye of our skilled staff to spot these possible defects before any tank reaches the public.